Ana amfani da tsarin sanyaya ruwa na nitrogen a cikin masana'antar semiconductor & guntu, gami da aiwatar da,

- Fasahar Molecular Beam Epitaxy (MBE)

- Gwajin guntu bayan kunshin COB

Samfura masu dangantaka

KYAUTATA KWALLIYAR BEAM

An haɓaka fasahar Molecular Beam Epitaxy (MBE) a cikin shekarun 1950 don shirya kayan fim na bakin ciki na semiconductor ta hanyar amfani da fasahar fitar da iska. Tare da haɓaka fasahar vacuum ultra-high, an ƙaddamar da aikace-aikacen fasaha zuwa fannin kimiyyar semiconductor.

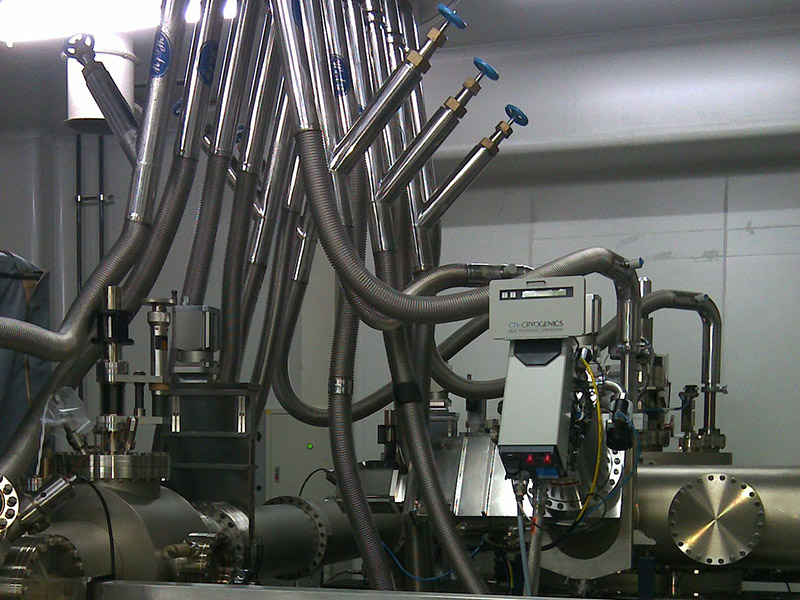

HL ta lura da bukatar MBE ruwa nitrogen tsarin sanyaya, shirya fasaha kashin baya don samun nasarar samar da wani musamman MBE ruwa nitrogen cooing tsarin for MBE fasaha da kuma cikakken sa na vacuum insulated bututu tsarin, wanda aka yi amfani a da yawa Enterprises, jami'o'i da kuma bincike cibiyoyin.

Matsalolin gama gari na semiconductor & masana'antar guntu sun haɗa da,

- Matsi na Liquid Nitrogen zuwa Kayan Aikin Tasha (MBE). Hana Yawan Matsi daga Kayan aikin Tasha Mai lalacewa (MBE).

- Mashigin Ruwan Cryogenic da yawa da Gudanar da fitarwa

- Matsakaicin Liquid Nitrogen zuwa Kayan Tasha

- Matsakaicin Adadin Fitar Gas na Cryogenic

- (Automatic) Canjawar Babban Layin Layi da Reshe

- Daidaita Matsi (Rage) da Kwanciyar VIP

- Tsaftace Rarraba Mai yuwuwa da Ragowar Kankara daga Tanki

- Lokacin Cika Kayan Aikin Ruwa na Tasha

- Precooling Pipeline

- Resistance Liquid a cikin Tsarin VIP

- Sarrafa asarar Nitrogen Liquid yayin Sabis na Tsarin

HL's Vacuum Insulated Pipe (VIP) an gina shi zuwa ASME B31.3 lambar bututun matsa lamba a matsayin ma'auni. Kwarewar aikin injiniya da ikon sarrafa inganci don tabbatar da inganci da ƙimar ƙimar shukar abokin ciniki.

MAFITA

HL Cryogenic Equipment yana ba abokan ciniki tare da Tsarin Bututun Insulated Vacuum don saduwa da buƙatu da yanayin masana'antar semiconductor & guntu:

1.Quality Management System: ASME B31.3 Matsa lamba Piping Code.

2.A Special Phase Separator tare da Multiple Cryogenic Liquid Inlet da Outlet tare da aikin sarrafawa ta atomatik ya dace da buƙatun iskar gas, nitrogen mai sake yin fa'ida da zazzabi na nitrogen na ruwa.

3.Adequate da kuma dacewa da ƙirar ƙira yana tabbatar da cewa kayan aiki na ƙarshe koyaushe yana aiki a cikin ƙimar matsa lamba da aka tsara.

4.An sanya Barrier na Gas-liquid a cikin bututun VI na tsaye a ƙarshen bututun VI. Gas-liquid Barrier yana amfani da ka'idar hatimin gas don toshe zafi daga ƙarshen bututun VI zuwa cikin bututun VI, da kuma rage asarar nitrogen ta ruwa yadda yakamata a lokacin katsewa da sabis na tsaka-tsaki na tsarin.

5.VI Piping Controlled by The Vacuum Insulated Valve (VIV) Series: Ciki har da Vacuum Insulated (Pneumatic) Rufe Valve, Vacuum Insulated Check Valve, Vacuum Insulated Regulating Valve da dai sauransu Za a iya haɗa nau'ikan VIV daban-daban don sarrafa VIP kamar yadda ake buƙata. An haɗa VIV tare da prefabrication na VIP a cikin masana'anta, ba tare da jiyya na kan layi ba. Ana iya maye gurbin sashin hatimi na VIV cikin sauƙi. (HL yana karɓar alamar bawul ɗin cryogenic wanda abokan ciniki suka tsara, sannan ya sanya bawul ɗin bawul ɗin HL. Wasu nau'ikan nau'ikan bawuloli da samfuran bawul ɗin ƙila ba za a iya sanya su su zama bawul ɗin da aka keɓe ba.)

6.Cleanliness, idan akwai ƙarin bukatun ga ciki tube surface tsabta. Ana ba da shawarar cewa abokan ciniki su zaɓi bututun bakin karfe na BA ko EP azaman bututun ciki na VIP don ƙara rage zubewar bakin karfe.

7.Vacuum Insulated Filter: Tsaftace mai yuwuwar ƙazanta da ragowar kankara daga tanki.

8.Bayan 'yan kwanaki ko tsayin rufewa ko kiyayewa, yana da matukar mahimmanci don precool da VI Piping da kayan aiki na ƙarshe kafin shigar da ruwa na cryogenic, don guje wa dusar ƙanƙara bayan ruwa na cryogenic kai tsaye ya shiga cikin VI Pipe da kayan aiki. Ya kamata a yi la'akari da aikin precooling a cikin ƙira. Yana ba da mafi kyawun kariya ga kayan aiki na ƙarshe da kayan tallafin bututun VI kamar bawuloli.

9.Suit don duka Dynamic da Static Vacuum Insulated (M) Tsarin Bututu.

10.Dynamic Vacuum Insulated (M) Tsarin Bututu: Kunshi na VI M Hoses da / ko VI Pipe, Jumper Hoses, Vacuum Insulated Valve System, Phase Separators da Dynamic Vacuum Pump System (ciki har da famfo famfo, solenoid valves da vacuum gauges da dai sauransu). Za'a iya keɓance tsayin tsayin VI guda ɗaya mai sassauci bisa ga buƙatun mai amfani.

11.Various Connection Types: Vacuum Bayonet Connection (VBC) Nau'in da Welded Connection za a iya zaba. Nau'in VBC baya buƙatar jiyya mai keɓaɓɓen wurin.