Matatar Na'urar Injin Tsafta ta OEM

Cire Najasa da Gurɓatawa Mai Inganci Don Inganta Aiki: Matatar Na'urarmu ta OEM Vacuum Cryogenic an ƙera ta musamman don cire ƙazanta da gurɓatawa cikin inganci daga na'urorin cryogenic a cikin tsarin injin. Fasahar tacewa mai ci gaba tana tabbatar da tsarki da amincin yanayin cryogenic, tana haɓaka aiki da tsawon rai na na'urorin. Ta hanyar kamawa da cire ƙazanta yadda ya kamata, matatarmu tana ba da gudummawa ga inganci da amincin hanyoyin cryogenic a cikin aikace-aikacen masana'antu daban-daban. Zaɓuɓɓukan da Za a iya Keɓancewa don Biyan Buƙatun Masana'antu na Musamman: Mun fahimci cewa hanyoyin masana'antu suna da buƙatu na musamman, saboda haka, Matatar Na'urar OEM Vacuum Cryogenic ɗinmu tana ba da zaɓuɓɓukan da za a iya keɓancewa don biyan takamaiman buƙatu. Tare da bambance-bambancen girma, ƙimar tacewa, da nau'ikan haɗi, muna samar da mafita na musamman waɗanda suka dace da takamaiman buƙatun tsarin masana'antu daban-daban. Wannan sassauci yana bawa abokan cinikinmu damar inganta aikin matatar a cikin takamaiman aikace-aikacen su, yana tabbatar da ingantaccen tacewa da dacewa. An ƙera shi da Mayar da Hankali Kan Inganci, Aminci, da Fasaha Mai Kyau: Matatar Na'urar OEM Vacuum Cryogenic ɗinmu an ƙera ta ne a cikin kayan aikinmu na zamani, inda inganci, aminci, da fasahar zamani suka zama dole ga hanyoyin samar da mu. Kowace matattara tana fuskantar gwaje-gwaje masu tsauri da matakan kula da inganci don tabbatar da aiki mai inganci da inganci a cikin mawuyacin yanayi na masana'antu. Ta hanyar haɗa fasahar zamani da mafita masu ƙirƙira, muna isar da matattara waɗanda suka dace da mafi girman ƙa'idodi na inganci, dorewa, da aiki a cikin tsarin injin tsabtace iska mai ƙarfi.

Aikace-aikacen Samfuri

Ana amfani da dukkan nau'ikan kayan aikin injinan da aka rufe da injinan iska a cikin Kamfanin Kayan Aikin HL Cryogenic, waɗanda suka wuce ta cikin jerin hanyoyin fasaha masu tsauri, don canja wurin iskar oxygen mai ruwa, nitrogen mai ruwa, argon mai ruwa, hydrogen mai ruwa, helium mai ruwa, LEG da LNG, kuma waɗannan samfuran ana yi musu hidima don kayan aikin cryogenic (tankunan cryogenic da flasks na dewar da sauransu) a cikin masana'antar raba iska, iskar gas, jiragen sama, kayan lantarki, superconductor, kwakwalwan kwamfuta, kantin magani, asibiti, bankin bio, abinci da abin sha, haɗa kai ta atomatik, roba, kera sabbin kayan aiki da binciken kimiyya da sauransu.

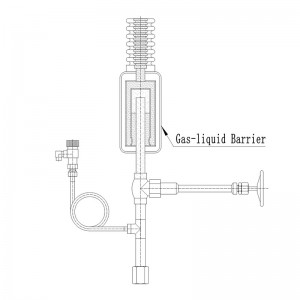

Matatar Injin Mai Rufewa

Ana amfani da matatar mai rufi da injin tace iska, wato matatar mai rufi da injin tace iska, don tace datti da kuma ragowar kankara daga tankunan ajiyar ruwa na nitrogen.

Matatar VI za ta iya hana lalacewar da ƙazanta da ragowar kankara ke haifarwa ga kayan aikin tashar, da kuma inganta rayuwar kayan aikin tashar. Musamman ma, ana ba da shawarar sosai ga kayan aikin tashar masu daraja.

Ana sanya matatar VI a gaban babban layin bututun VI. A cikin masana'antar kera, an riga an haɗa matatar VI da bututun VI ko bututun a cikin bututu ɗaya, kuma babu buƙatar shigarwa da maganin rufewa a wurin.

Dalilin da yasa ƙanƙarar ƙanƙara ta bayyana a cikin tankin ajiya da bututun da aka yi da injin tsabtace iska shi ne lokacin da aka cika ruwan cryogenic a karon farko, iskar da ke cikin tankunan ajiya ko bututun VJ ba ta ƙarewa da wuri ba, kuma danshi a cikin iska yana daskarewa lokacin da ya sami ruwa cryogenic. Saboda haka, ana ba da shawarar sosai a tsaftace bututun VJ a karon farko ko don dawo da bututun VJ lokacin da aka yi masa allura da ruwa cryogenic. Purge kuma yana iya cire dattin da aka ajiye a cikin bututun yadda ya kamata. Duk da haka, shigar da matatar da aka rufe da injin tsabtace iska zaɓi ne mafi kyau kuma ma'auni mai aminci biyu.

Don ƙarin tambayoyi na musamman da cikakkun bayanai, tuntuɓi Kamfanin Kayan Aikin HL Cryogenic kai tsaye, za mu yi muku hidima da zuciya ɗaya!

Bayanin Sigogi

| Samfuri | HLEF000Jerin Jeri |

| Diamita mara iyaka | DN15 ~ DN150 (1/2" ~ 6") |

| Matsi na Zane | ≤40bar (4.0MPa) |

| Zafin Zane | 60℃ ~ -196℃ |

| Matsakaici | LN2 |

| Kayan Aiki | Bakin Karfe Jerin 300 |

| Shigarwa a kan shafin | No |

| Maganin da aka makala a wurin | No |